Great little mini in the shop for a very minor repair, but brought back some fond memories of working on, modifying, tinkering, racing and navigating these great little machines.

Good times.)

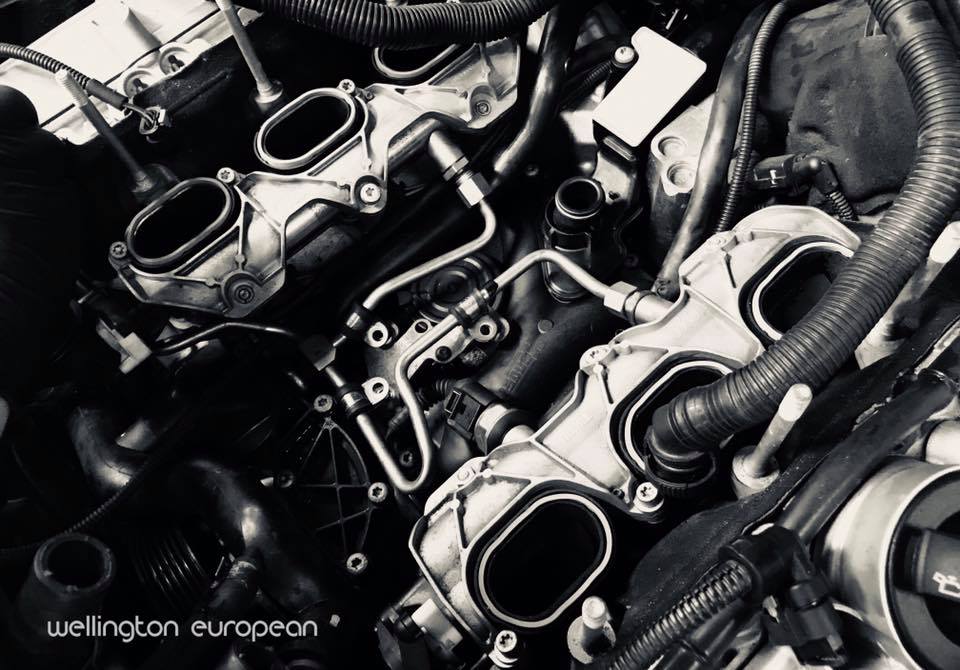

BMW I3 in for service inspection, This car does have a small petrol engine which was up do date, the rest of the usual service type checks still apply, It still has brakes and tyres, etc etc. Fun little car, the owner insisted i take it for a drive… Loved it.

After a small break (wife having a child) its time to make some moves with little blue. I have been accumulating parts in the mean time, so we have ready to go, new front swivel kits, all new seals and gaskets, new wheel bearings, and axle bearings. As per the rear axle (Part2) I will be doing new brakes also, likely the only original brake parts with be the backing plates and adjusters, so new cylinders, shoes, return springs, drums etc.

4/5/19 was day one of getting back into it, the axle was front axle assembly was already largely stripped, so now it clean up and time for some fresh paint. Ideally a lot of these components could have been sand blasted (or similar) etc which we don’t have on site, and this is an exercise of resurrecting this old truck on a limited budget. That said it was time to get dirty with a wire brush, wire wheels in a drill…. The end result I am very happy with.

Want to see Part 1 & 2… CLICK HERE

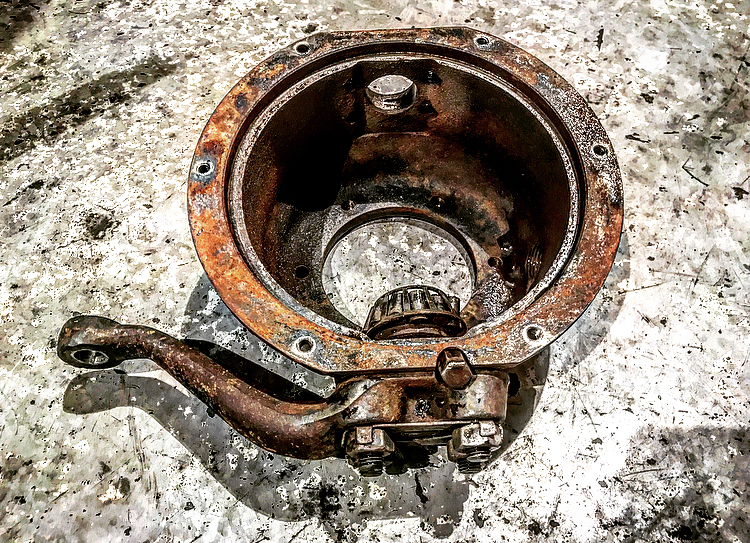

First pic is what we started with, total mess, collapsed wheel bearings, play and slop in everything, 27 years of farm use without a wash…)

Winters on… June 1 and I’m in the back of the shop with little blue. Some good progress today. I was donated some axles from my good friend Paul, who I blame for introducing me to landies.. I’ve removed and replaced the bearing and seal collars. Also assembled the RH front swivel assembly to the diff housing, set up preloads etc. Diff is on hold, needing shims to set up the pinion bearing pre-loads. (

For 5 years we had 3 E46 BMW’s running around town. The name change was a great opportunity for trade up to newer, with fewer kms.

So 2 of the BMW’s have been sold and gone to new homes. TOY001 I just couldn’t let go….Maybe its time??

So we have added a MK5 Golf GT,

And new to us, not yet signed up is a 2010 MK6 Golf wagon.

Also yet to be decided on is the A4 Audi in the background. This might be the new TOY001 if i can finally part with my old BMW

Wow I cannot believe it but we are coming up on a year on from re-branding. What a wild ride its been.

We’ve done everything we set out to do 12 months ago, We’ve added a hoist, bought more tools, changed up the loan cars and more…

BUT!!

There’s always more to do, improvements to make, and more cars to service and repair…

Watch out for the 12 month summary blog!! And whats up next…

New to the blog and want to check out part one of Little Blue/ Check it out here—- LittleBlue

I thought I would kick off with Part two after having a wee break from Little Blue, there has been some weekend progress, however some family commitments have take over my weekends for a while….)) (With a little land Rover helper on the way)..

So here is a little of the more recent progress. Last featured we had a complete stripped down landy, chassis on stands, and I had made a start on the rear axle..

Chassis repairs are well under way, hopefully in the next week or two all the new outriggers will be on and the new cross member as well.

Below, completed rear axle tidied up, this was a complete mess. Diff itself was in good order, have renewed everything brake related, shoes, drums, cylinders, hose, pipes etc. Also wheel bearings ands seals etc, came up nice.

Hows that for a before and after!!

Next up is the front axle, strip down has started.

Chassis updates, well the rear top section was a patchwork quilt, and when removing the tub we found only one bolt holding it on.. (oh and gravity). So its had farm repairs or bush repairs and is in need of some professional help. So in goes some new steel, out comes the straight edges and measuring tapes.. Happy with progress so far.

Tacking in some new steel!!

Below, rtear homemade crossmember has been removed and we ar getting ready to fit the new re-production part..

New on the market and at the time of posting this, not yet advertised.

Any information wanted, contact john@wellingtoneuropean.co.nz and I will put you in touch with the owner.

Serious buyers only.

We see our fair share of high end machines, but its not everyday we get a Lamborghini through the front door.

Here’s a weeu sample from July, some very nice cars, were plenty more but missed my chance with the camera….

Recent Comments

What others have to say