Check out these massive stoppers! These things are absolutely huge. Huge power under the bonnet requires matching huge stopping power to match. Nice Genuine fitment here, we also have some nice aftermarket options out there for these.

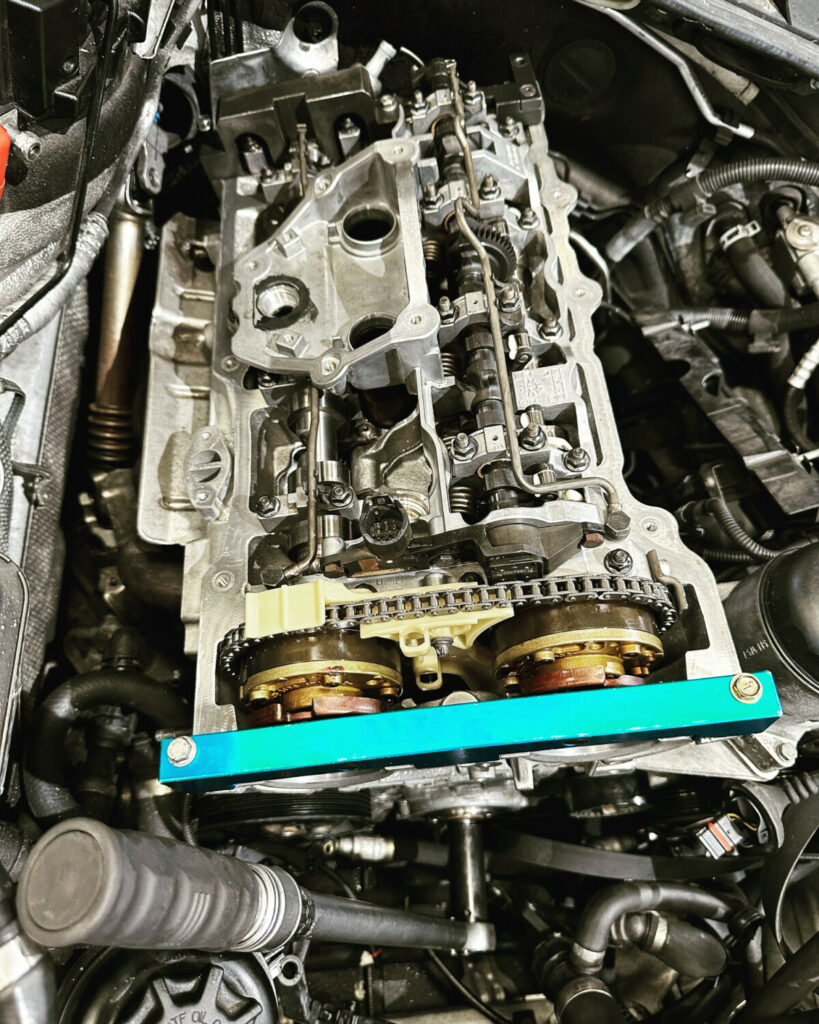

BMW in for heavy oil consumption. The car was performing fine however the oil usage was high. Tests came back with using about 1Litre of oil per 1000km’s. Thankfully this owner had a mechanical breakdown insurance who came to the rescue and paid for a large portion of the repairs. As it turned out we did 2 of these jobs in August.

Both with policy’s through different providers. This one required ‘exhaust’ valve guides and valve stem seals. A reasonably common issue. The work involved removing the cylinder head for inspection and repairs as required. The owner in this case opted to renew the timing chain ‘kit’. The timing tool in ‘blue’ is fitted here as we ‘time’ the engine and torque up the crank and cam pulleys.

Our car TOY006 was in for brakes and then its twin arrives for the same job. Snap, hit repeat in the shop.

This car presented with warning lights on the dash and a lack of performance, going into limp mode. Turbo pressure codes., removal of the turbo we found the manifold cracked, leaking exhaust pressure. This is a reasonably common fault and this engine and turbo has a few applications, Land Rover, Ford and Volvo. Unfortunately these manifolds are made up of a double stainless skin and aren’t easily repaired. Reports of internal pieces breaking away and completely destroying the turbo. A nice Monday job fitting a new turbo on an updated aftermarket manifold to prevent the same fault re-occuring.

2 Range Rover Evoques in for work. Diesel had a service and a tune while the Petrol had rear brakes replaced. Nice to start seeing a few of these coming through the shop.

Quick visit to the British and European car day today, prompted me to pull a few photos from a few years ago when I took my Cortina, which is currently locked up in the back corner of the shop needing some attention. Lack of time so the poor cars being neglected.

We are calling this our Stage 3 clean. Stage 1 being Hydrogen Carbon clean machine. Stage 2, Hydrogen Carbon Clean machine and Liquimoly intake cleaner.

Stage 3 Walnut Blasting

Stage 4 = All of the above

What is it? quite literally its a machine that uses compressed air and fine crushed walnut shells to remove carbon build up. In our application, usually intake ports and the back sides of intake valves.

Why do it? Alot of modern engines by design are prone to carbon build up in the intake system, over time as the carbon build up increases the efficiency of the engine reduces, meaning less performance, fuel economy etc.

Why now for WEEU? We deal with a lot of cars that suffer from carbon build up, and a lot of our customers like to keep there cars no only going, but going like they should! We follow a lot of forums and in recent times have seen a lot of discussion on this topic. We also dont know of many local workshops that offer this service so decided now was the time. Its also a good fit with our other Detox Tools and Tuning service we now provide.

Whats involved? There is some time involved and the time taken varies from car to car. We do have to remove the intake manifold to gain access to the intake ports, this can mean on some cars, intake runner flaps also need removing. Each cylinder is done separately as the valves need to be in the closed position so as to not fill the cylinder with walnut shells, all other ports are masked off etc to avoid walnut shells going where they are not wanted.

Great feedback from the customer re the end result. We could tell from start up that the car just sounded crisper and more responsive.

We are experiencing more and more cars that are down on power due to a combination of intake and combustion areas being built up with carbon, largely reducing the efficiency and power. We have invested in a ‘OxyHydrogen Carbon Cleaning’ Machine. This machine is run through the intake system to clean the combustion area, which can be done without any major dismantling. To take things to the next level we have also purchased a ‘Walnut Blaster’. Walnut blasting of the intake system does require some dismantling/removal of the intake system to gain excess. However removing these large carbon deposits with allow the engine to breath again. Restoring power and fuel economy = more fun and more bang for your buck at the pump.

The Carbon Cleaning machine wont do the intake manifold and intake valves which generally require more invasive work, We do have a Walnut blasting machine for this service if you are serious about regaining some engine efficiency…

Some of the first cars run through the Carbon Cleaning process. all cars will be different, I felt instant improvement in my Mercedes.)

How does HYDROGEN clean carbon deposit in the engine?

The Hydrogen Carbon clean unit runs on distilled water and electricity. The hydrogen and oxygen are produced using a mix of distilled water and electrolysis, this is then feed into the engine via the air intake/breather hose or air box.

The increased internal oxygen proportion improves combustion and at the same time the catalytic properties of hydrogen make it possible for the combustion carbon to be gradually broken down to clear the internal carbon deposits.

A strong electric current splits the water molecule (H2O) into its component atoms producing highly charged particles of hydrogen and oxygen, or oxy-hydrogen (HHO). The HHO is passed into the engine and burnt as the engine runs mixing the HHO with the fuel. As it passes through the induction system, combustion chamber, exhaust etc, the hydrogen reacts with the carbon deposits turning the carbon into hydrocarbons, this lifts the carbon deposits from the engine and the resulting gas exits the engine via the exhaust system.

Using no harsh chemicals the treatment returns your engine to a state of cleanliness. You regain power and performance, restore lost MPG and drastically cut emissions.

After treatment, there is no need to change engine oil or any type of filter.

The machine acts to restore the optimum performance of your engine. Using hydrogen technology, carbon deposits are removed from the inner workings of the engine, which naturally build up during the lifetime of the vehicle.

By removing unwanted carbon build up, further engine deterioration and damage can be avoided. This will keep your engine working more effectively and smoothly for longer, creating an enhanced driving experience.

The technology works with all types of vehicle’s – from motorbikes to planes if it has a combustion engine then it can be cleaned. Both petrol and diesel and LPG engines will show improvements irrespective of vehicle age and/or value.

Recent Comments

What others have to say